HOME < News < WLINK AIoT Platform successfully used in the intelligent monitoring system for the electrolytic tank in Zambia

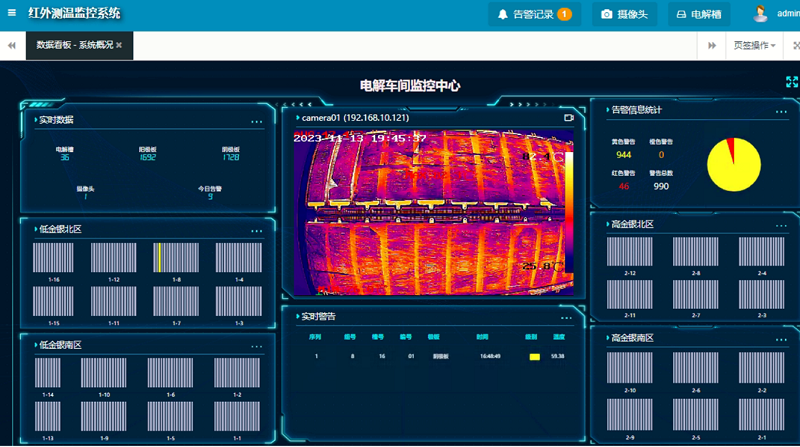

On September 12th 2024, after three months of installation, debugging, and on-site acceptance, the technical renovation Wlink digital AIoT comprenesive management platform - the online intelligent monitoring system for the electrolytic tank surface - was successfully put into use. The system increased the current efficiency from 93.5% to 97.2%, and the management of the electrolytic tank surface shifted from manual detection to intelligent online monitoring mode.

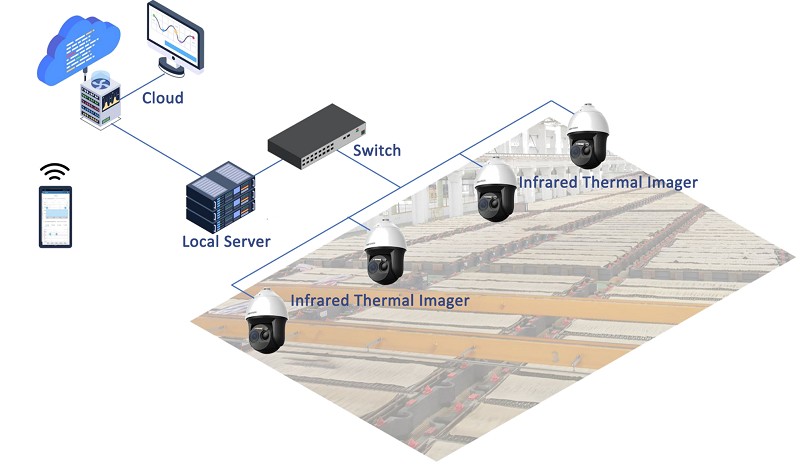

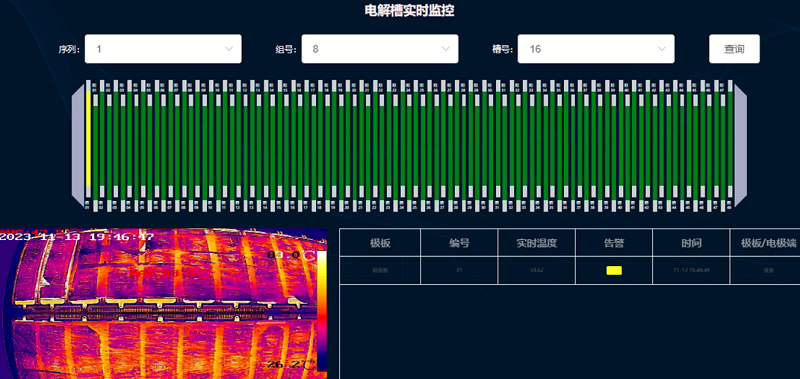

The system utilizes infrared temperature measurement technology, cloud computing technology, and big data combined with professional monitoring equipment to construct a software and hardware system. The front-end monitoring probe of the system is fixedly installed on the top of the electroplating workshop. The high-precision photoelectric turntable of the probe is equipped with a high-resolution "dual spectrum" camera, which performs online 24-hour uninterrupted cruise scanning of the electroplating tank plates, and transmits the temperature and image information of each electroplating tank plate obtained through the network to the back-end workstation for analysis and processing, achieving accurate identification & positioning of short-circuit plates in the electroplating tank.

The successful application of this system has solved the problems of high labor intensity, low detection efficiency, and untimely processing in manual detection, strengthened the management of the production process, and helped the cooperated LME cathode copper manufacturers improve the level of intelligent equipment in the cathode copper production process.

-- The end