HOME < < 2025, Deep Integration of Industrial IoT and AI

2025, Deep Integration of Industrial IoT and AI

At the beginning of 2025, the release of DeepSeek V3/R1 became the focus of attention in the science and technology community and even the whole society, marking a major breakthrough in China's artificial intelligence field. This progress is not only exciting, but also opens up broader prospects for the future development of AI technology.

The combination of Industrial Internet of Things (IIoT) and artificial intelligence (AI) has long been deepening in exploration and practice, and has reshaped the industrial landscape at an unprecedented speed. This integration is not only a manifestation of technological innovation, but also a core driving force for promoting industrial transformation, improving production efficiency, and optimizing resource allocation.

As an extension of the Internet of Things in the industrial field, the IIoT realizes real-time data collection and transmission by connecting a large number of devices, machines and sensors to the Internet. Data shows that in 2024, the number of connected devices in the world has exceeded 17 billion, among which the growth of industrial Internet of Things devices is particularly significant. These devices are like the "nerve endings" of the industrial system, continuously collecting key data such as equipment operation status, production progress, and product quality.

Artificial Intelligence (AI), on the other hand, serves as the "intelligent brain" of industrial systems. It possesses powerful capabilities in data analysis, pattern recognition, and decision-making, enabling deep mining and analysis of the massive data collected by IIoT. From machine learning to deep learning, the continuous evolution of AI technology enables machines to learn from data and make intelligent decisions without a lot of human intervention.

I. Technology Integration: the Leap from Data to Intelligence

1. AI-Driven Real-Time Analysis and Predictive Capabilities

The IIoT collects massive amounts of data in real-time through sensors and edge devices, while AI technologies (especially machine learning and deep learning) imbue this data with "intelligence." For example, AI algorithms can analyze sensor data such as equipment vibration and temperature to predict machine failures and trigger maintenance instructions in advance, thereby reducing unplanned downtime. This predictive maintenance not only relies on the learning of historical data, but also simulates the operating status of physical equipment through digital twin technology to dynamically optimize maintenance strategies..

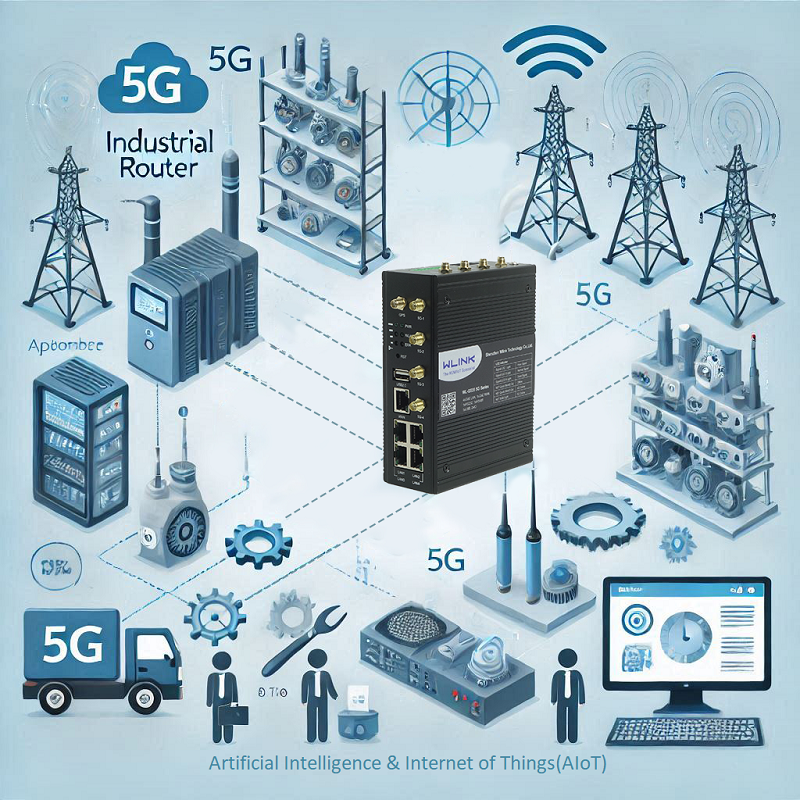

2. 5G and AIoT as Foundational Support

The high bandwidth and low latency of 5G networks provide the infrastructure needed for the convergence of IIoT and AI. For instance, in smart logistics, AI algorithms combined with real-time 5G-transmitted warehouse data can dynamically optimize inventory management and logistics routes, significantly reducing warehousing costs.

3. Synergy between Edge Computing and AI

As industrial scenarios demand higher real-time performance, edge computing has become a critical enabler of IIoT and AI integration. By deploying AI models near data sources, enterprises can achieve millisecond-level response speeds. For example, in smart factories, edge nodes can analyze production line images in real-time, using computer vision to detect product quality defects and immediately adjust equipment parameters to avoid large-scale defective production. This approach not only reduces latency and costs associated with cloud transmission but also enhances data privacy protection.

II. Challenges and Responses

1. Data Security and Privacy Protection

As more devices become connected, a large amount of sensitive industrial data is transmitted and stored over networks. How to prevent data from being stolen or tampered with and ensure production safety has become a problem that needs to be solved urgently.

2. Compatibility Issues

The compatibility issues between IoT devices and systems from different manufacturers cannot be ignored. The lack of technical standardization and interoperability hinders the widespread adoption of IIoT and AI integration.

3. Reliability and Stability Requirements

Industrial applications have extremely high requirements for reliability and stability, as any failure could lead to significant losses. Therefore, when designing an AI system, it is essential to consider the accuracy of algorithms, as well as the robustness and real-time responsiveness of the system.

Challenges also represent the direction of progress. In 2025, the convergence of industrial IoT and AI has become an unstoppable trend. Despite the challenges, continuous technological advancements and innovations will bring transformative changes and development opportunities to the industrial sector and society as a whole.

WLink Technology has consistently focused on and promoted the application of AI technology in the industrial IoT field. Several AIoT solutions, such as the "Intelligent Inspection and Positioning System for Electrolyzer Surfaces" and "AI Safety Production Applications," have been deployed in multiple global projects. Moving forward, Dechuan will continue to prioritize customer needs, driving the ongoing integration of industrial IoT projects and AI.

-- The end