HOME > Case > Energy > 5G Router used in Smart Mining Application

Background

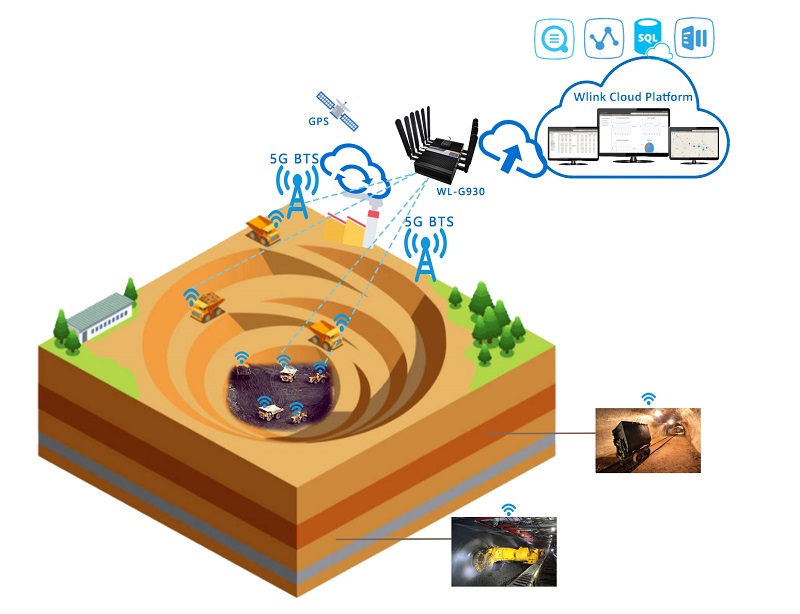

With the depletion of mineral resources, mining operations face increasing challenges, heightened safety risks, and escalating management costs. In response, the industry is embracing 5G technology combined with cloud computing, big data, IoT, and other advanced solutions. These innovations enable automated mine planning, real-time sensing during excavation, intelligent transportation management, and self-optimizing operations. The result is improved productivity and enhanced economic efficiency in mining operations.

WLINK 5G Solution

Mining sites are often located in remote areas with limited network coverage, making a dedicated network essential. The WLINK 5G router is an ideal solution for these conditions because:

Easy Deployment:

5G networks are faster to deploy than traditional wired solutions, reducing installation complexity and costs.Superior Performance:

With faster transmission speeds, lower latency, and support for a higher number of connected devices, 5G enables the establishment of secure VPN networks and precise positioning (within 1 meter), which can even replace traditional GPS solutions.Robust Connectivity:

By integrating WLINK 5G routers into key mining equipment—such as rock drills, excavators, robot trucks, and dump trucks—a stable, low-latency network connection is achieved. This connectivity supports real-time remote control and monitoring, including the transmission of live video and sensor data back to a centralized monitoring center.

Why use 5G mobile network?

1. Lower Operating Costs

By digitizing critical mining assets through embedded sensors and a 5G network, operators can predict maintenance needs, reduce downtime, and lower labor, cable, and maintenance costs.

2. Enhanced Autonomous Operations

The low latency of 5G is crucial for enabling autonomous driving and operation of mining equipment. Real-time data transmission to cloud servers allows for centralized processing and rapid decision-making, facilitating smoother and safer automated operations.

3. Improved Mine Safety

Advanced predictive maintenance, enabled by 5G connectivity, minimizes accident risks. Remote monitoring allows for the safe operation of unmanned vehicles and machinery, reducing the need for personnel to work in hazardous environments. Smart sensors continuously capture and transmit safety-related data, allowing for real-time oversight and rapid response to any issues.

4. Proactive Equipment Monitoring

The operations control center can monitor equipment status online via the 5G network, predict potential failures, and initiate timely maintenance or part replacements. This ensures that all mining equipment operates at peak efficiency and reliability.

Related Products

WL-G930 /G530 series 5G router

Industrial robust, heavy-duty metal enclosure for shock and high vibration environments

High data speed via 5G or 4G+ network, 4G/3G backward compatible

VPN and encryption technology ensure data security

Strong electromagnetic interference Resistance

Built-in watch dog, Multi-link detection

Gigabit Ethernet ports for networking flexibility