HOME > Case > Industry > Smart Warehousing Monitoring Solution

1. Background

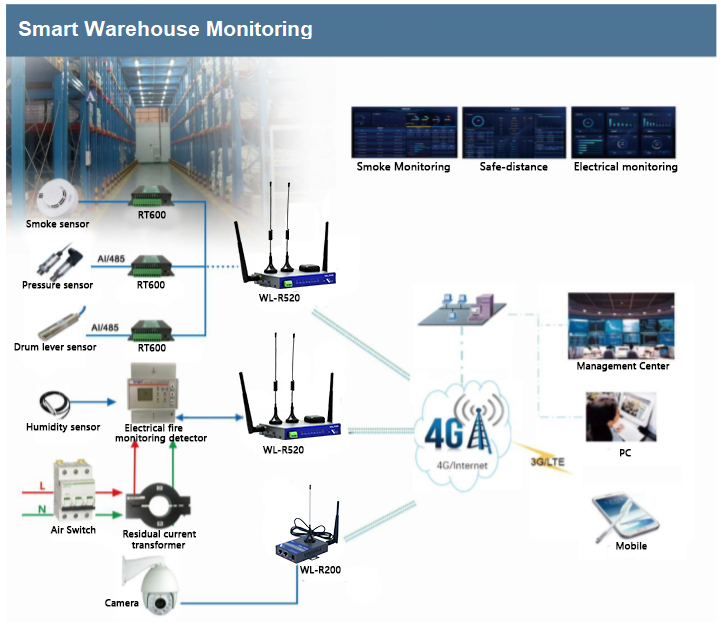

With the rapid expansion of the modern logistics industry, the demand for storage space has grown considerably. However, increased storage capacity also brings new safety challenges. For example, cargo may block fire hydrants, obstruct fire exits, or impede access to emergency passages. Additionally, electrical short circuits, and inadequate temperature, humidity, water level, or pressure in fire hydrant systems can compromise overall warehouse safety. To address these risks, continuous, remote monitoring of warehouse environments is essential.

2. WLINK Solution

WLINK leverages cutting-edge IoT technology to integrate smart monitoring into warehousing systems, replacing manual inspections with automated, data-driven oversight. By combining big data collection, real-time analysis, fault detection, and emergency alerts, WLINK’s solution delivers timely and accurate information that significantly enhances warehouse safety management.

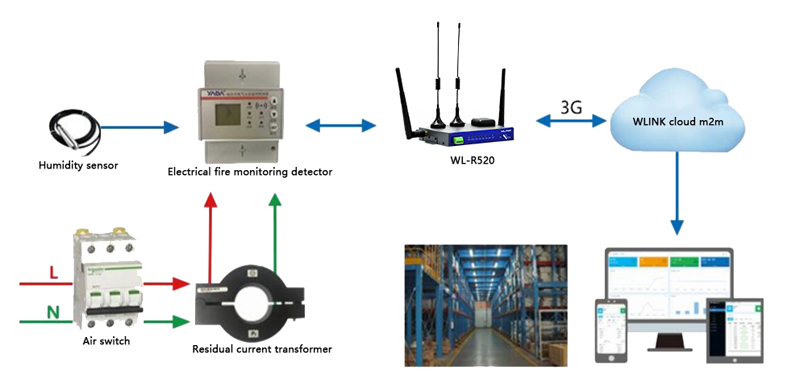

2.1 Electrical Safety Monitoring

How It Works:

Electrical sensors, including residual current transformers and temperature sensors, continuously monitor key parameters.Response Mechanism:

When anomalies such as overcurrent or abnormal temperature readings are detected, data is sent to the central monitoring system. If a potential fire hazard is identified, the WLINK Cloud M2M Platform immediately issues a fire alarm and sends an SMS alert to designated personnel.

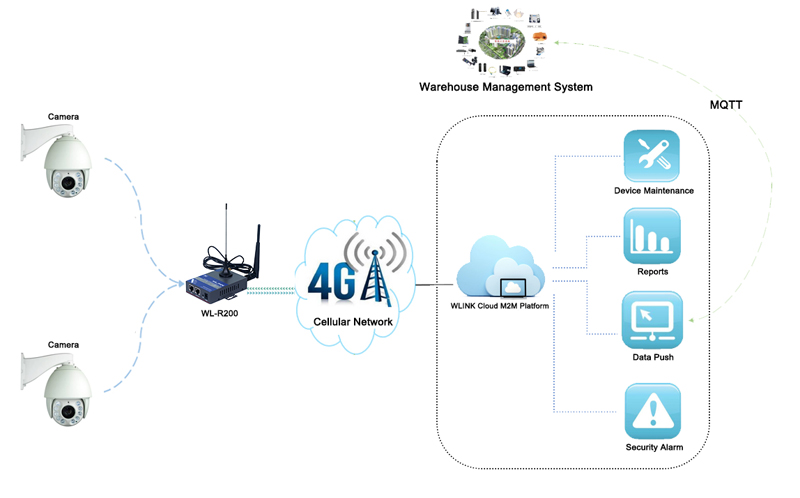

2.2 Fire Exit Monitoring

System Components:

Utilizes IP cameras integrated with the WL-R200 wireless router.Functionality:

Intelligent algorithms analyze images captured by the IP cameras to detect any obstructions or unauthorized activity at fire exits. When an issue is identified, images and alerts are transmitted over a 3G/4G network to the WLINK Cloud M2M Platform, which then sends SMS alerts to responsible staff.

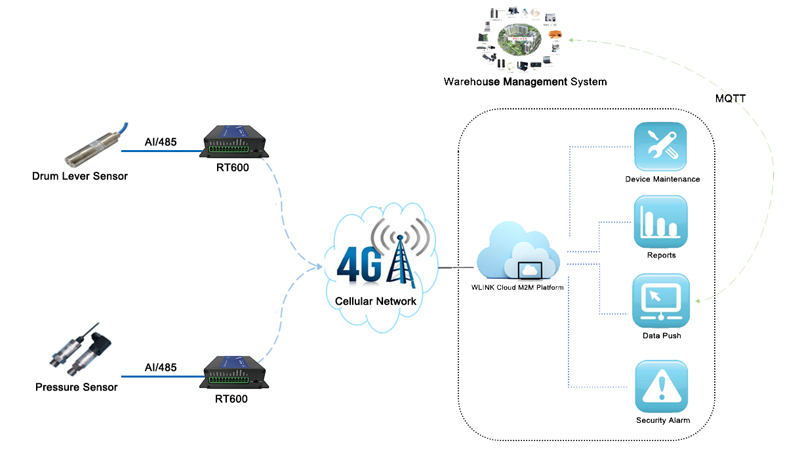

2.3 Fire Pipe Network Monitoring

Sensors Involved:

Pressure sensors and liquid level sensors are installed within the fire pipe network.Data Transmission:

The WL-RT600 RTU collects data on water tank levels, firefighting equipment pressure, and sprinkler pressure, transmitting this information in real time via the 3G/4G network.Alert System:

Any abnormal readings trigger an immediate SMS alert to the relevant personnel via the M2M platform.

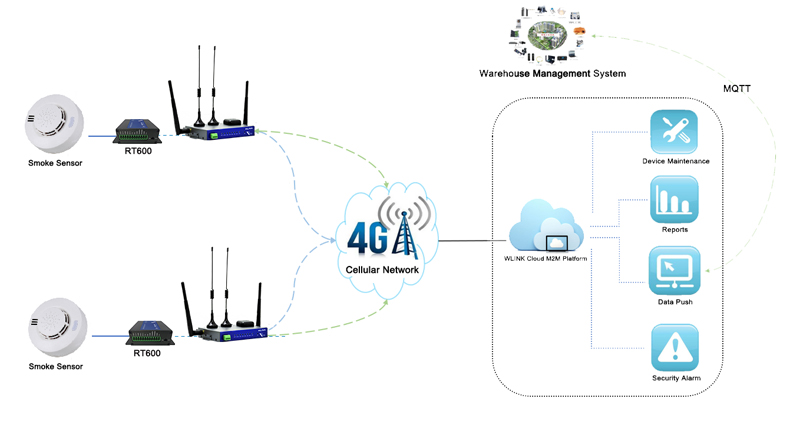

2.4 Smoke Monitoring

Monitoring Approach:

The WL-RT600 RTU collects signals from battery-powered wireless smoke sensors, including smoke, switch, and battery voltage signals.Alarm Protocol:

In the event of smoke detection, sensor removal, or any other irregularity, the RTU promptly sends alarm data to the server, and the WLINK Cloud M2M Platform dispatches an SMS alert to notify staff.

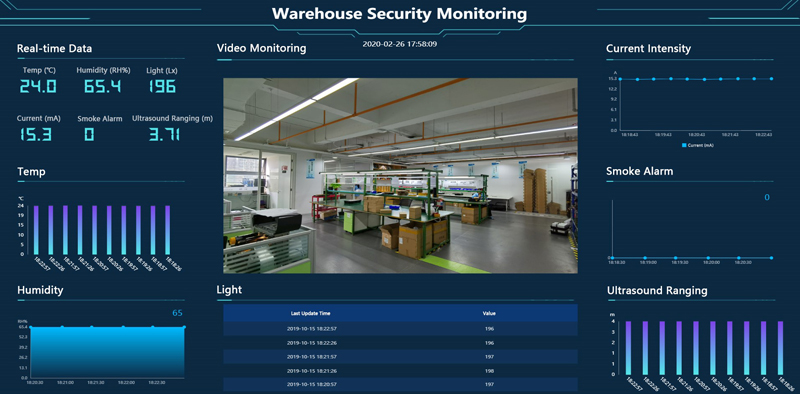

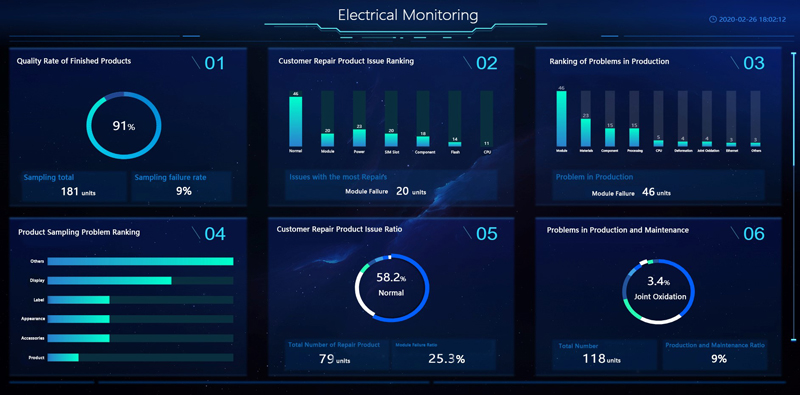

2.5 Monitoring Status Display

Display contents can be customized according to requirements.

1) Warehousing Security Monitoring

2) Electrical Monitoring

3) Smoke Monitoring

3. Related Products

3.1 WL-R520 and WL-R200 series 3G/4G router, basic features includes:

Industrial robust design and compact metal housing

Strong electromagnetic interference Resistance, heat endurance and radiation ability

Ultra security, VPN: PPTP, L2TP, GRE, IPSec and OpenVPN

Built-in watch dog, Multi-link detection

Always online, reboot automatically if disconnected to ensure continual connection

WL-R520 support dual SIM backup or failover, WL-R200 with single SIM

3.2 WL-RT600 RTU

Industrial robust, heavy-duty metal enclosure for shock and high vibration environments

Strong electromagnetic interference Resistance

Built-in watch dog, Multi-link detection

Multiple operation modes

Rich Serial and I/O interfaces

Programmable for user-defined I/O, Modbus and CANBus.

-- The end