HOME > Case > Industry > 5G Smart Manufacturing

Background

Smart Manufacturing, also known as Industry 4.0 or the "Factory of the Future," represents a significant shift from legacy systems to interconnected, data-driven processes. In modern industrial environments, reliable, secure, and ultra-fast connectivity is essential to capture and process real-time data for monitoring plant equipment and driving predictive maintenance. With its high capacity, low latency, and enhanced mobility, 5G provides the ideal last-mile connectivity required for smart manufacturing.

WLINK Solution

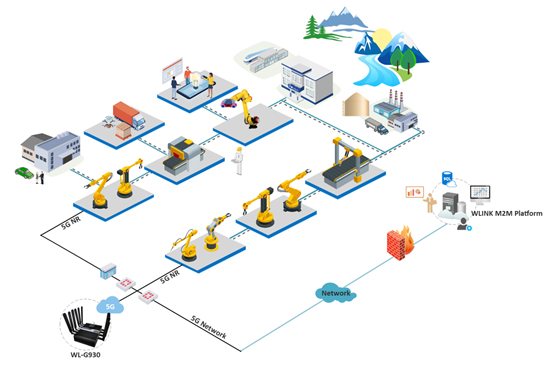

In today’s complex factories—populated with intelligent robots, advanced machinery, and numerous sensors—establishing a high-speed, stable network connection is crucial. WLINK 5G routers seamlessly integrate into these environments, linking robots, machines, and sensors to cloud servers. This robust connectivity enables real-time monitoring, precise data analysis, and coordinated control of production processes. The result is enhanced automation, increased flexibility, and improved overall productivity. With WLINK’s 5G solution, manufacturers can better evaluate equipment performance, optimize production planning, and maintain an efficient supply chain across the entire facility.

Smart Manufacturing Features

1. Factory Automation

Dynamic Reconfiguration:

5G’s high density, speed, and low latency allow for rapid re-purposing of tools and robots, enabling mass customization and on-demand manufacturing.

2. Process Automation

Real-Time Data Collection:

Continuous monitoring of machinery, inventory, and production processes facilitates detailed analysis of production patterns. This insight allows for optimal sequencing of factory activities, maximizes workflow, and reduces waste.

3. Human-Machine Interface (HMI)

Enhanced Mobility:

With 5G, staff are no longer tethered to fixed terminals. Mobile data and visualization tools—such as tablets and augmented reality devices—empower employees with immediate, visual interactions with machines and products.

4. Supply Chain Integration

End-to-End Connectivity:

5G improves digitization, tracking, and real-time monitoring within the supply chain. IoT trackers enable buyers to monitor goods in transit, while autonomous trucks leverage 5G to adapt to dynamic traffic conditions, ensuring seamless logistics operations.

5. Preventive Maintenance

Predictive Analytics:

Dense sensor networks provide comprehensive equipment data, enabling scheduled and predictive maintenance. This proactive approach minimizes unscheduled downtime and enhances remote diagnostics through advanced analytics, ML, and AI.

6. Safety

Enhanced Protection:

A wide array of sensors combined with near-instantaneous 5G response times creates a safer manufacturing environment. With fewer personnel required on the factory floor and rapid emergency shut-off capabilities, workplace safety is significantly improved.

Return of Investment

Optimized Maintenance:

Real-time equipment monitoring combined with predictive analytics minimizes unexpected downtime and maintenance costs.Improved Efficiency:

Enhanced process automation and quality control—enabled by 5G-connected robotic systems and advanced visual recognition—lead to higher productivity and reduced waste.Robust Security:

Built-in security features and the ability to replace traditional networks in remote areas provide manufacturers with confidence in their IoT infrastructure.Superior Tracking:

5G facilitates seamless asset, logistics, and workforce tracking both within and outside the plant, enhancing overall operational efficiency and safety.

Related Products

WL-G930 /G530 series 5G router

l Industrial robust, heavy-duty metal enclosure for shock and high vibration environments

l High data speed via 5G or 4G+ network, 4G/3G backward compatible

l VPN and encryption technology ensure data security

l Strong electromagnetic interference Resistance

l Built-in watch dog, Multi-link detection

l Gigabit Ethernet ports for networking flexibility

l Rich interfaces such as GBE, serial port, IO, USB ports

-- The end