HOME > Case > Industry > CNC Machines Remote Wireless Monitoring

Background

CNC (Computerized Numerical Control) machines are sophisticated mechatronic systems that integrate mechanical, computer, hydraulic, sensing, information processing, optical, and mechanical technologies. Because any failure can lead to extended downtime, which in turn delays production and causes significant losses, timely maintenance is critical. Traditional maintenance methods require engineers to be physically present, resulting in slow response times and high operational costs. To address these challenges, WLINK introduces a remote monitoring solution that minimizes downtime and streamlines maintenance.

WLINK Solution

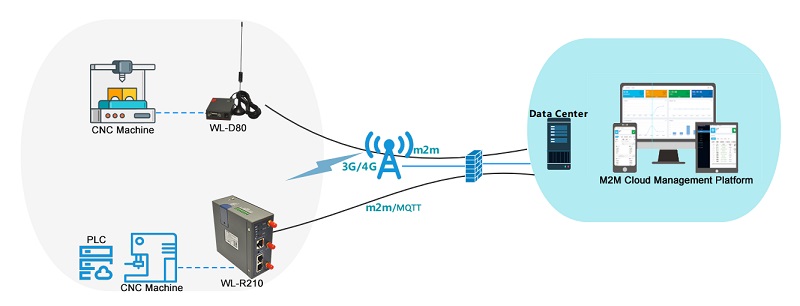

WLINK’s remote monitoring system utilizes R210 routers and D80 modems to connect CNC machines to an M2M cloud platform via a reliable wireless 4G network. This system automatically collects and transmits real-time data on machine operating conditions. By continuously monitoring and analyzing the performance of CNC functions, the platform can promptly alert users to any anomalies or changes, enabling swift intervention to maintain optimal equipment performance.

System Architecture

Router for Robust Connectivity:

The R210 router and D80 modem deliver a stable and reliable network connection with automatic reconnection capabilities to handle any dropouts.Real-Time Alarms:

Integrated I/O ports trigger immediate alarm events when changes in machine status are detected. These alarms are sent via SMS or directly through the M2M platform to notify maintenance engineers.Data Monitoring and Analysis:

The M2M platform continuously collects operational data, providing real-time insights for diagnosing the status of CNC machines and enabling proactive maintenance.

Benefits

Industrial-Grade Durability:

Constructed with a robust, compact metal housing that operates reliably in temperatures ranging from -30°C to +70°C.High Reliability:

Features automatic reboot from disconnections and faults to ensure 24/7 online operation.High-Speed 4G LTE Access:

Leverages fast 4G LTE connectivity for seamless data transmission.Flexible Interface Options:

Offers RS232/RS485 connectivity, along with 3 configurable I/O ports for both input and output signals.Protocol Support:

Compatible with Modbus RTU and Modbus TCP, with optional GRE, L2TP, PPTP, IPSec, Wireguard, Zerotier and OpenVPN for secure communications.Quick Deployment:

M2M device management platform software is easy to install and configure, with customizable features to suit special project requirements.

Related Products

WL-R210 3G/4G Router

WL-D80 RS232/RS485 serial to IP Modem

WL-D82 RS232+RS485 serial to IP Modem

-- The end